Divisions & Services

The Automotive Aftermarket / Vehicle Lifetime Solutions division is responsible for the global spare parts business and delivers innovative repair solutions in original-equipment quality. Under the brands LuK, INA, and FAG we offer clutch and release systems, engine and transmission applications, as well as chassis applications.

With REPXPERT, we offer support in everyday garage life: online portal, training, special tools, technical information or service hotline – here you get all technical services from a single source.

Services for garages

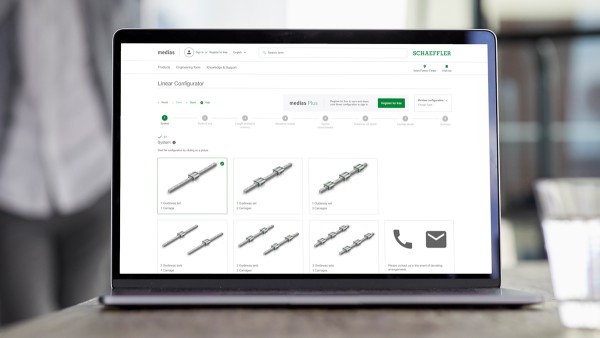

The product selection and information system for rolling bearings, plain bearings and linear guidance systems.

Product catalog medias

Are you interested in a brief introduction to BEARINX-online? In this introduction, we present e. g. the user interface and the theory and creation of a calculation model.

Request brief introduction BEARINX-online (in German)